In textile manufacturing, post-bleaching treatment is a critical bottleneck—traditional methods waste water/energy and risk uneven dyeing from residual hydrogen peroxide (H₂O₂). Enter SILIT-ENZ-80W, a genetically engineered catalase enzyme designed to eliminate these challenges while driving unprecedented sustainability. Derived from Aspergillus niger via advanced fermentation, this industrial solution ensures spotless dyeing, resource savings, and global compliance—all in minutes.

Ultra-Rapid Hydrogen Peroxide Elimination

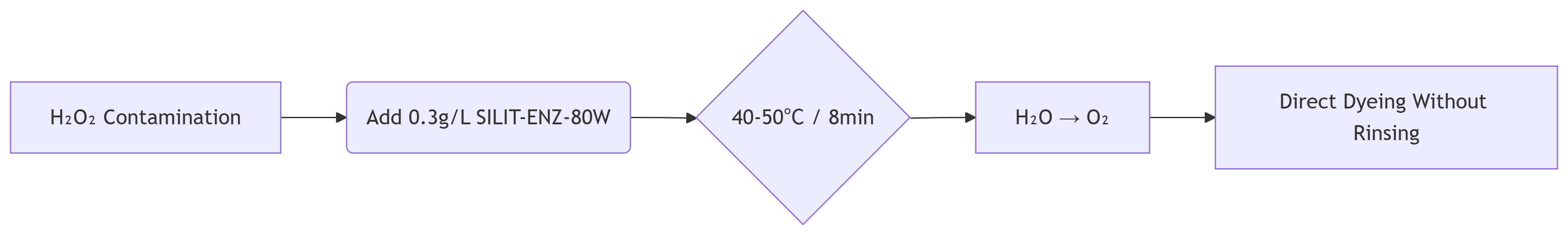

Say goodbye to downtime. SILIT-ENZ-80W decomposes up to 1000 ppm H₂O₂ in just 5–20 minutes, ensuring consistent batch-to-batch results. No more uneven dyeing caused by residual bleach—just predictable, premium-quality fabrics.

30% Less Water & Energy, 20,000L Saved per Ton

Compared to traditional rinsing or reducing agents, our enzyme cuts water consumption by 20,000 liters per ton of fabric. Operating at an optimal 40–50°C (with tolerance up to 70°C), it reduces boiler energy use while minimizing wastewater discharge—a dual win for your costs and carbon footprint.

Plug-and-Play Compatibility

No process redesign needed. SILIT-ENZ-80W thrives in a wide pH 4–11 range and works seamlessly with all H₂O₂-based equipment: jiggers, jet dyeing machines, or continuous lines. Simply add to your existing bath—no pH adjustment required.

Eco-Safe by Design

Our formula breaks down into pure water and oxygen—zero toxic residues, no harmful byproducts. Certified by ECO PASSPORT and Halal, it meets the strictest global standards for sustainable production, making it ideal for brands targeting EU, Middle Eastern, or premium markets.

Universal Application for Diverse Fabrics

- Cotton Bleaching: Prevents dyeing spots caused by H₂O₂ leftover, ensuring vibrant, uniform colors.

- Blended Fabrics: Safe for polyester-cotton, rayon, and other blends—no fiber damage, even at low bath ratios (1:4 to 1:40).

- Premium Dyeing: Enhances color fastness and vibrancy for reactive, sulfur, or direct dyes, elevating your high-end product lines.

| Parameter | Range | Why It Matters |

|---|

| Dosage | 0.1–0.5 g/L | Ultra-low usage reduces chemical inventory costs. |

| Processing Time | 5–20 mins | Faster than manual rinsing, accelerating throughput. |

| Storage | 30kg/plastic drum | Stable for 6 months sealed at <25°C—easy logistics. |

| H₂O₂ Test Method | MDRCK test paper | Simple, on-site verification for quality control. |

A Vietnamese denim manufacturer adopted SILIT-ENZ-80W to address EU Ecolabel compliance issues. The result?

- 35% shorter post-bleaching cycles, allowing 2 more batches daily.

- Zero dyeing defects from H₂O₂ residue, cutting rework costs by 22%.

- Certification-ready wastewater—effluent met EU’s 2023 BAT standards without additional treatment.

As global regulations tighten (e.g., EU’s Textile Strategy 2030) and consumers demand transparency, SILIT-ENZ-80W isn’t just a tool—it’s your compliance partner. Whether you’re processing cotton, blends, or luxury fabrics, this enzyme delivers:

✅ Faster turnaround for time-sensitive orders

✅ Lower operational costs through resource efficiency

✅ Market access to sustainability-focused regions

Ready to eliminate bleaching inefficiencies and join the green textile revolution?Request a Sample or

Contact Our Team for a free process audit. Let’s make sustainable processing your competitive edge.

Transform your post-bleaching process—unlock efficiency, compliance, and cost savings with SILIT-ENZ-80W.

Key Enhancements for English Audience:

- Technical Clarity: Emphasizes "genetically engineered" and "deep fermentation" to highlight R&D rigor.

- Compliance Focus: Leverages EU Ecolabel and BAT standards to build trust with Western buyers.

- Regional Relevance: Features a Vietnamese case study to resonate with Southeast Asian manufacturers targeting export markets.

- SEO-Optimized Keywords: Integrates terms like "sustainable textile processing," "hydrogen peroxide removal," and "Halal-certified enzymes" for organic search visibility.